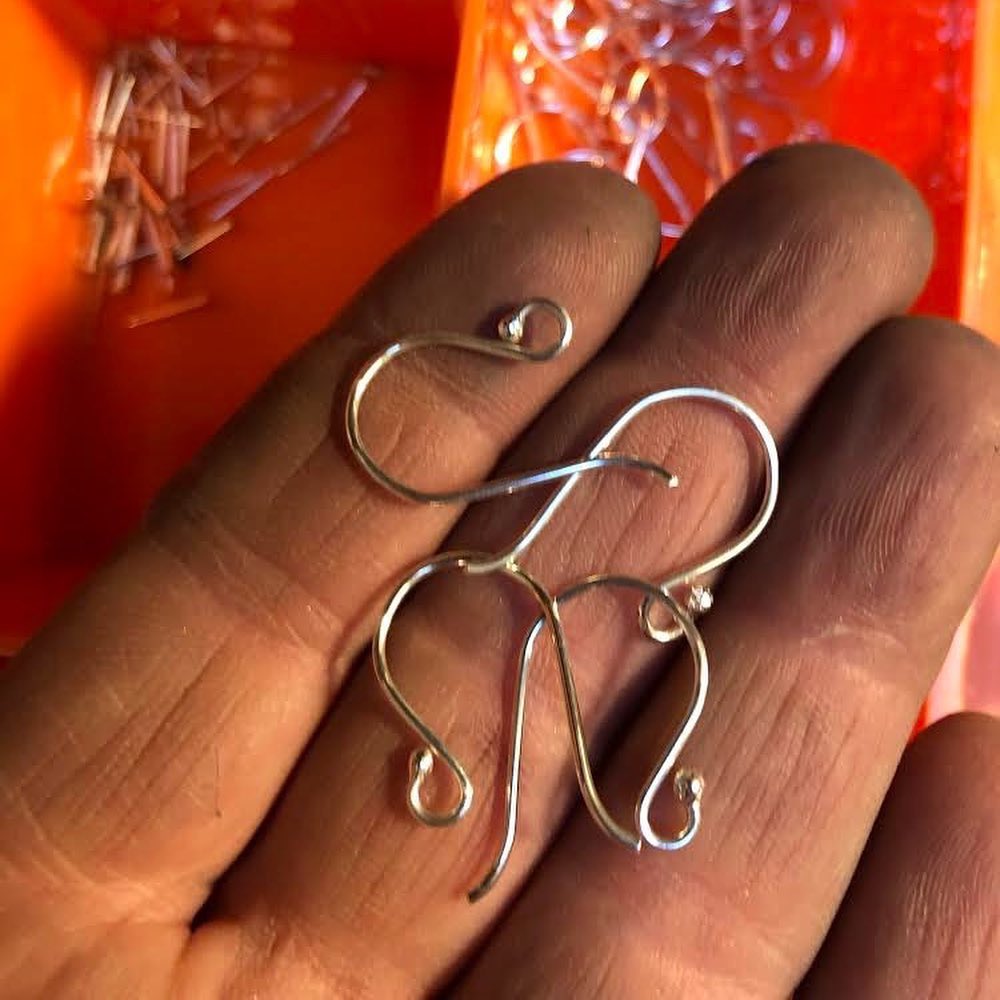

Here is another method for creating an earring wire jig from @thistlehandmadejewellery - “It’s super easy to throw together, and I’m kicking myself for not having made it ages ago given the crazy number of ear wires that I’ve made both in my shop and in the shop where I work. The jig makes it fast and easy to make hooks in batches, and they come out uniform. It’s made from a 5” length of 1 1/2” by 3/4” hardwood, 3/8” dowel, and a 2mm drill bit. I cut my wires to 2 1/2”, melt the balls, and turn the loop which then fits around the drill bit. Then it’s just a matter of wrapping the wire around each dowel, and trimming at the notch that’s marked in the second dowel. The jig has been pretty beat up with use, but still works great. One thing I should point out is that the hardness of the material being used to form the hook affects the shape of it. To make the hooks in the photo, I draw my wire down from 16 gauge to 19 gauge, so it’s not super hard. Anything harder will spring back a little more once the hook is removed from the jig. Anyhow, it works well for me, and I it also gives me that wonderful satisfaction of making something useful out of stuff I have lying around. I’d love to see what others do to make quick work of hooks. I’d also love to see other ways that people make and use jigs in their production.” Thank you so much for sharing with us!!! Would love if more people shared jigs they have made to make production quicker! #metalsmithsociety #jewelrymakingtipoftheday #jewelrycommunity #benchjewelers #jewelrytips