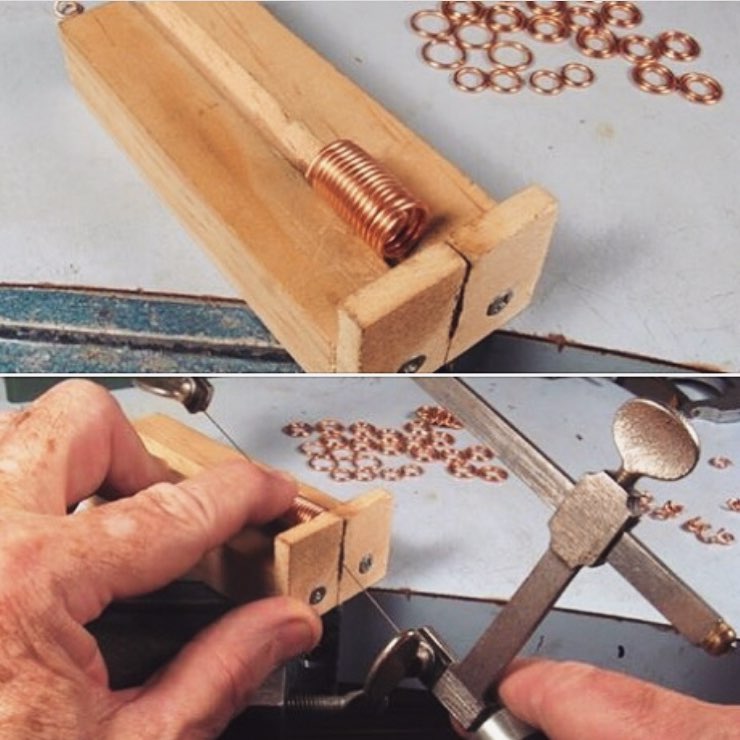

If you are serious about making jump rings, @riogrande posted this ingenious rig for cutting them. - “The difficult part of making #jumprings for me has always been holding the coil while cutting off the individual rings. I use a saw to get the best fit when closing the rings later. I've seen all sorts of suggestions for ways to hold the coil, but the one that works best for me is this little jig made from scrap wood.

It's about 2 inches wide and 4-5 inches long with a groove cut down its length to cradle the coil of wire and a thin stop attached to the front end.

To cut the rings, thread your saw blade through the coil, hold the coil down in the groove and against the front stop, and saw through the bottom of the coil at about a 40 degree angle.

Don't forget to use some wax or cutting lube (#BurLife!). It really does make a difference. If you don't believe me, do an experiment while you're cutting a lot of rings. Count how many rings can be cut before the blade breaks. First, do the test without lube, and then do it again while adding some lube to the blade after cutting every 8-10 rings. - BenchTips on Facebook” What is your method?#metalsmithsociety<br>#RioJeweler #maker #metalsmith #jewelrydesign #benchhacks #jewelersbench #instasmithy #handcraftedjewelry #sawing #sawingjumprings