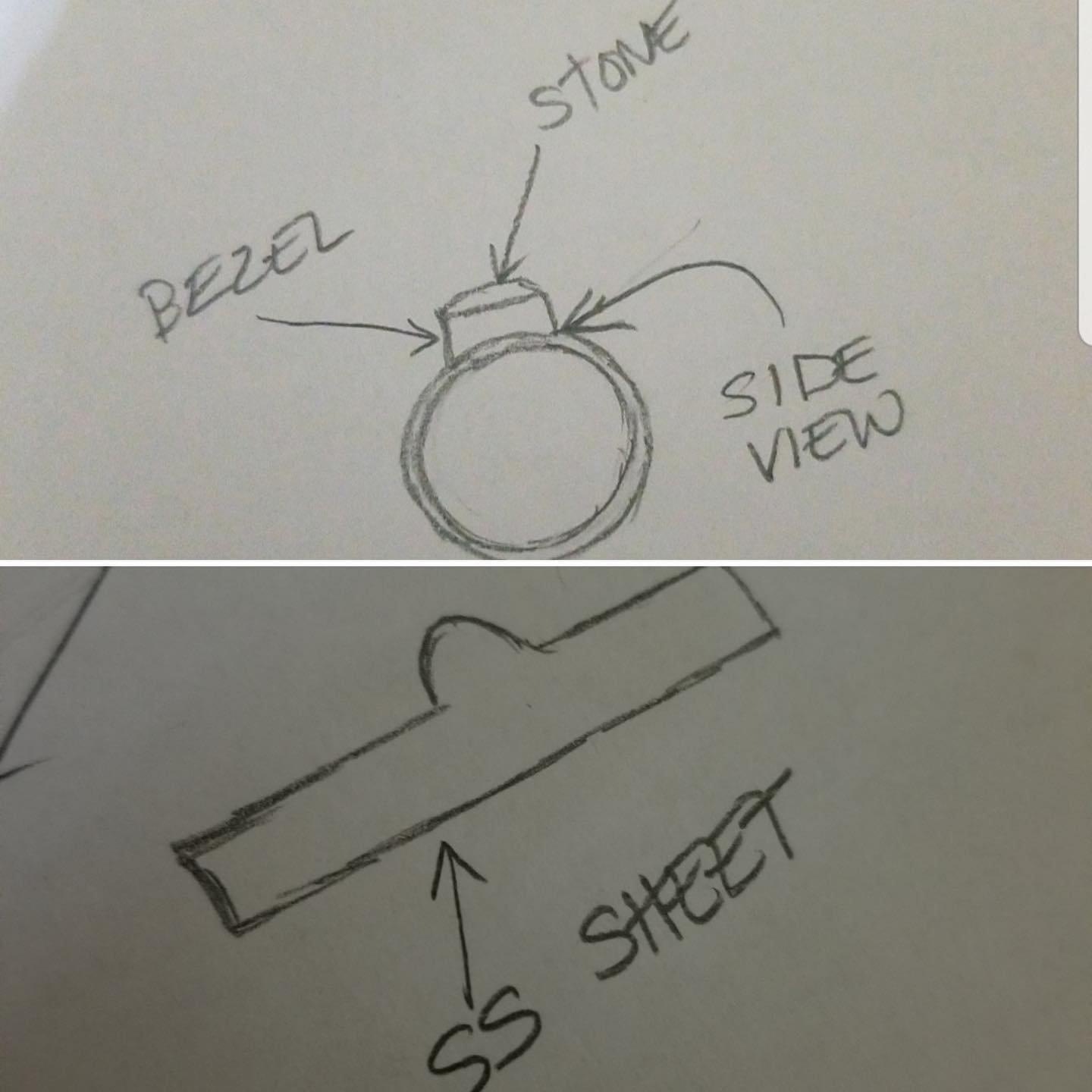

Here is a tip for soldering a bezel onto a curved surface from @theloveleighlocket - “If you want to incorporate a bezel into a wide band ring and use the band as the backplate...you will have to file the bottom of the bezel into a curved shape to make it flush. I didn't want to have to eyeball it and use a curved needle file to try to get the shape correct to flushly sit against the ring shank. So, I laid a piece of sandpaper over my ring mandrel (on the area of the size of ring I needed)...and moved the bezel back and forth vertically up and down the mandrel in short motions. This filed down the back side of the bezel into a curved shape and it fit perfectly flush onto the already curved/formed band I was using. Then, I was able to solder it perfectly onto the ring band and not have an extra piece of metal for a backplate. I dont like the look of a super high stone, so this worked out great! *Due to the curvature of the ring, be sure to make a seat on the inside of the bezel area so your stone won't rock side to side before setting it." Thank you so much for sharing this! Years ago we did share this technique but considering we have about 100,000 new people in our community I think it’s safe to revisit this amazing idea (and others as well!) I am totally happy to reshare a tip we’ve shared in the past! I find people have their own take, their own way of describing and their own photos. Thanks Amy! #bezels #bezelsetting #solderingbezels #stonesetting #cabochons #settingcabochons #makingjewelry #makingabezelsetting