Here is a tip for making uniform earring wires, every time from @spritzfireandice - “I follow a 3 part method that produces consistently reliable results when making ear wires with balled ends. I prefer 21 guage Argentium Silver as the balls I melt are perfectly smooth after forming and tumbling, no sanding required.

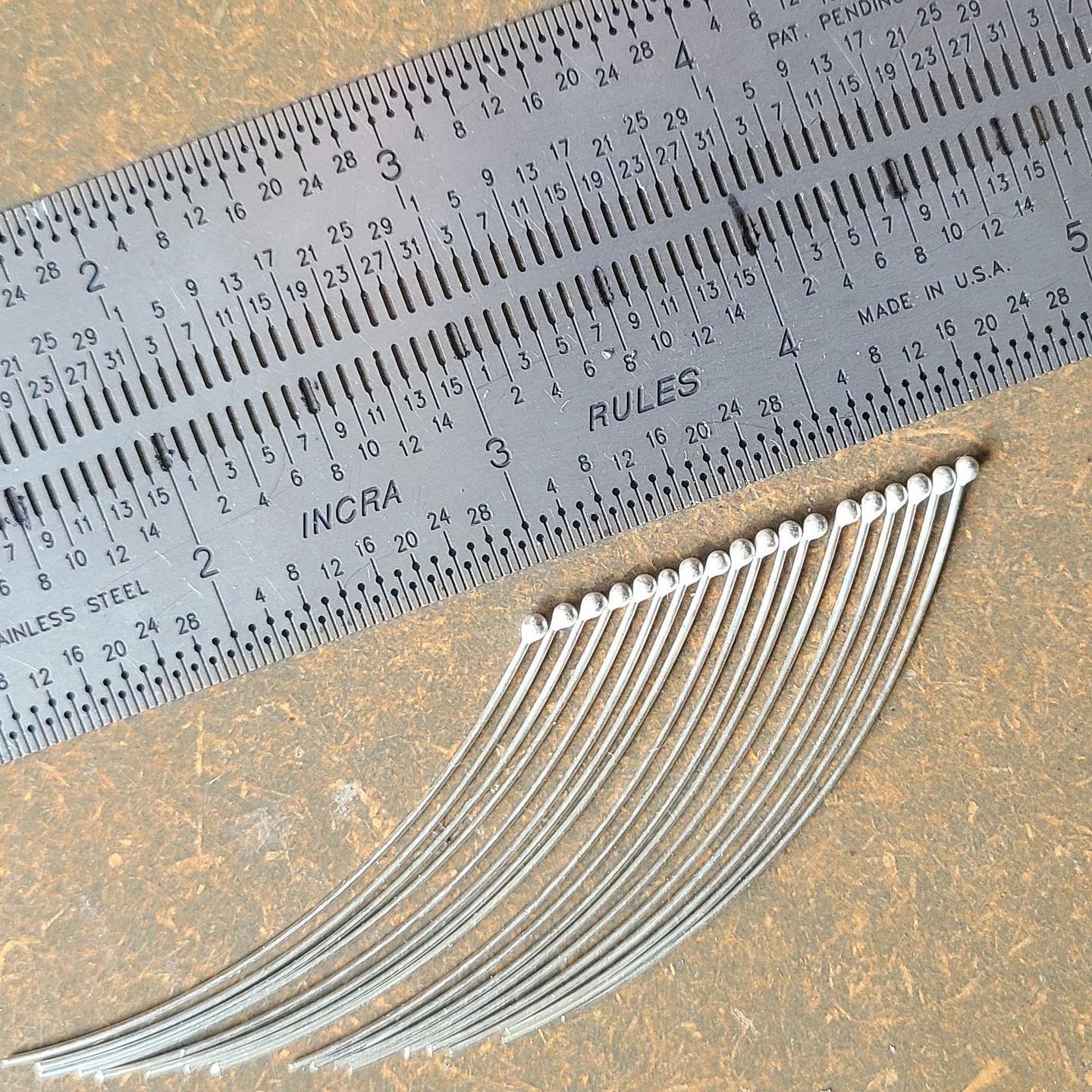

1️⃣ I secure the coil of wire on my bench pin so I don't have to chase it around my bench. I place a ruler on my bench pin. I measure, cut, then use the first piece as my standard to cut the next wire. You can cut multiples this way, dropping each successive cut into your sweeps catcher. I place the bottom of my flush cutters against the length of the first wire, then cut the coiled wire I've lined up against my template wire. This gives me two exact lengths if I've taken the time to line up the top ends of the wire. I cut these wires at 2 3/4". (Be sure to include the length of the balled wire when calculating the length of your wire cuts.)

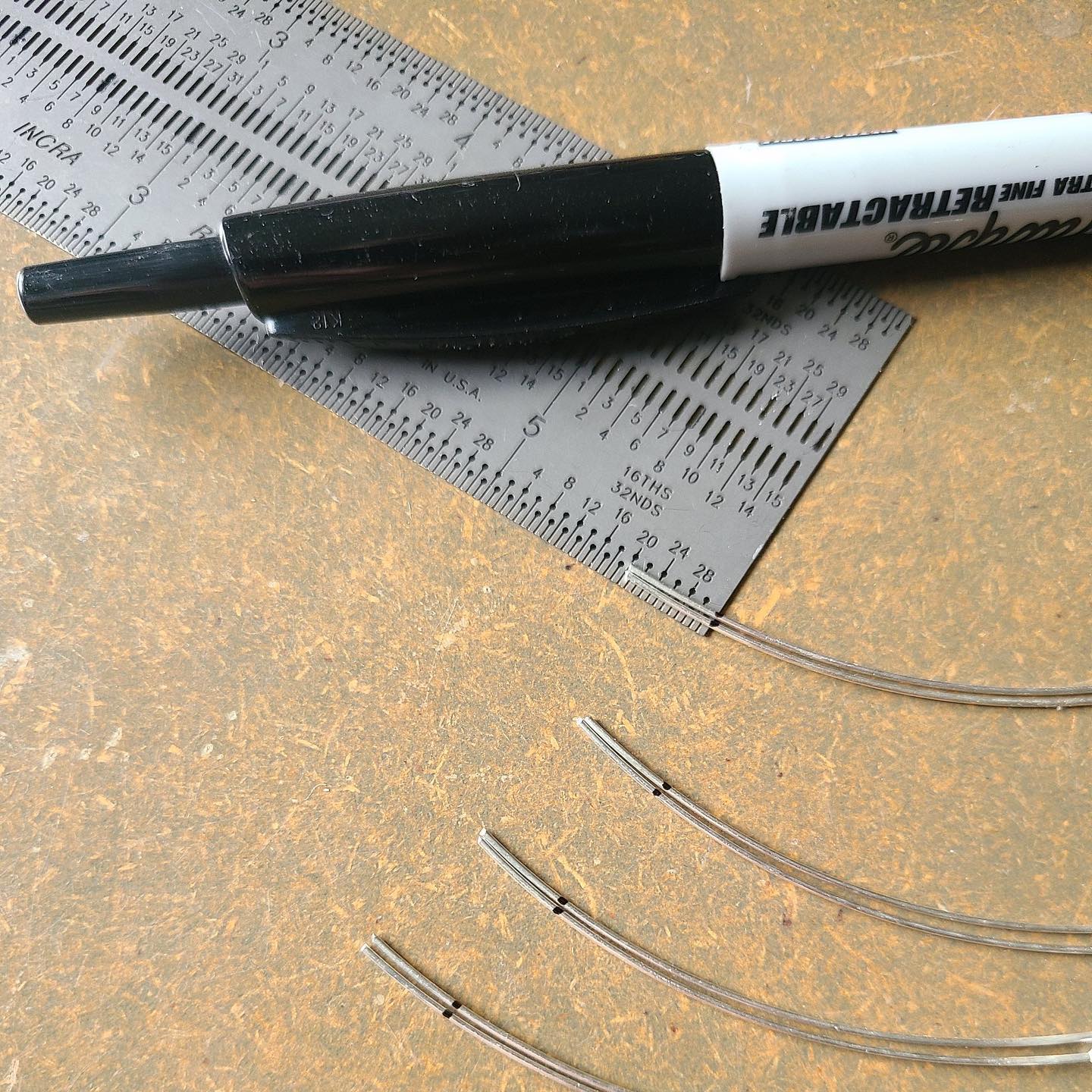

2️⃣ to guide me in melting the wire to consistent diameters, I pair two cut lengths on a ruler, mark across both wires at exactly 3/8", using a time-saving retractable Sharpie.

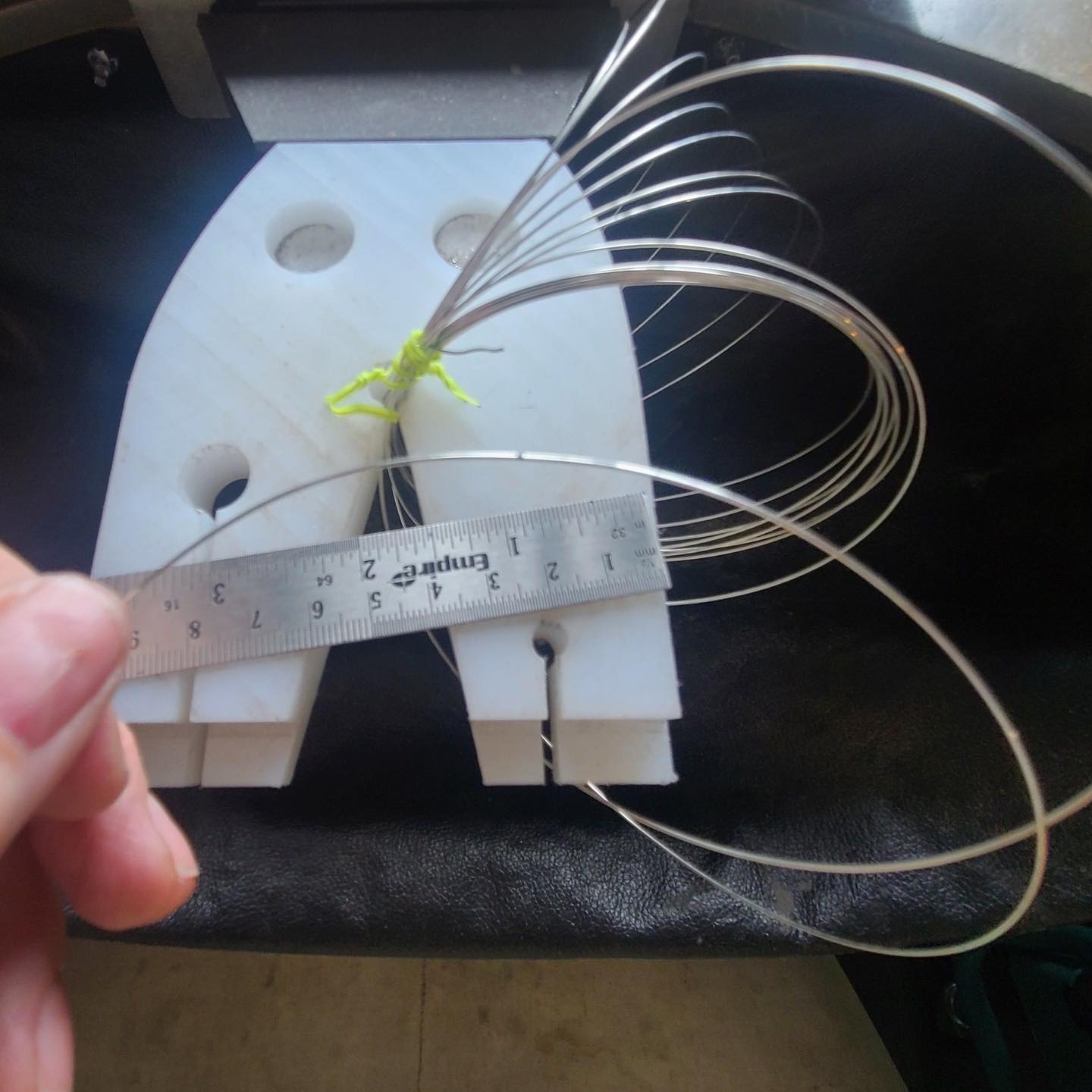

3️⃣ at my soldering bench I typically use all my soldering and third hand tweezers. I line them up with one wire held in each pair, with the Sharpie mark facing me. This mark tells me when to remove my torch as the wire is melting into a ball and traveling up on itself. I apply the heat to the bottom tip of a wire, watch carefully as the silver melts, and I stop immediately once the black line disappears. I drop each wire into my quench bowl as I go and place the tweezers on the tile on my bench to cool. This part goes very quickly for me. I repeat the process if there are remaining wires to be balled. I then move all the balled wires into the pickle bath. Once pickled, neutralized, rinsed and dried, I begin the next phase of forming and hardening my ear wires.” Thank you Di, marking the wire for a visual on how far to melt is 🤯 we appreciate this SO MUCH. #makingearringwires #makingearrings #jewelrymaking