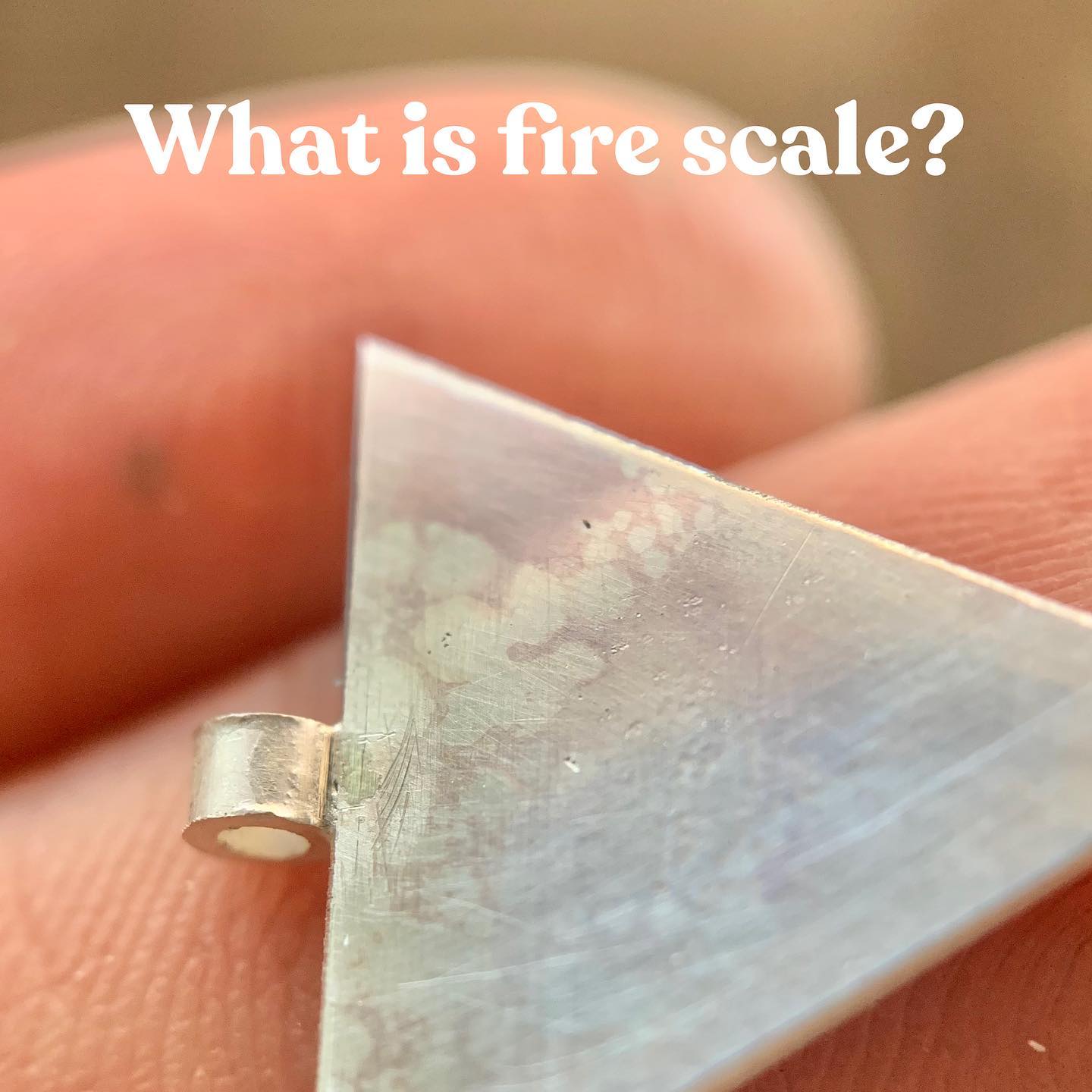

PREVENTING FIRESCALE - To explain the cause of firescale I have borrowed an exert from Tim McCreight’s Complete Metalsmith if you don’t own that book it is an essential and you can find on my book recommendations page!! - “When copper bearing alloys (like sterling silver) are heated in the presence of oxygen, oxides are quickly formed. Cupric oxide is a black surface layer that can usually be dissolved in pickle. Cuprous oxide is a purplish compound that forms simultaneously within the metal. This is firescale.” I often get asked by members of our community what can be done to prevent fire scale, since it can be time consuming to remove. The best advice I have is to get in the habit of putting your work in a bath of denatured alcohol and boric acid, burn off the alcohol and then flux and solder your work! This simple step before you flux and solder will not only help prevent fire scale but it’s also inexpensive! This glass container I’m using is available from our sponsor @gesswein.jewelry and is perfect for storing your alcohol/boric acid mix. 🚨You want to make sure the cover is on and the container is moved out of the way before you light your torch. This mixture is VERY flammable! :) Thank you to Gesswein for supporting the page, you can find this container (Item 830-2320 ) and tons of other great tools over on their website and you can save 5% by using code MSS5. #firescaleprevention #solderingjewelry #solderingjewelryforbeginners