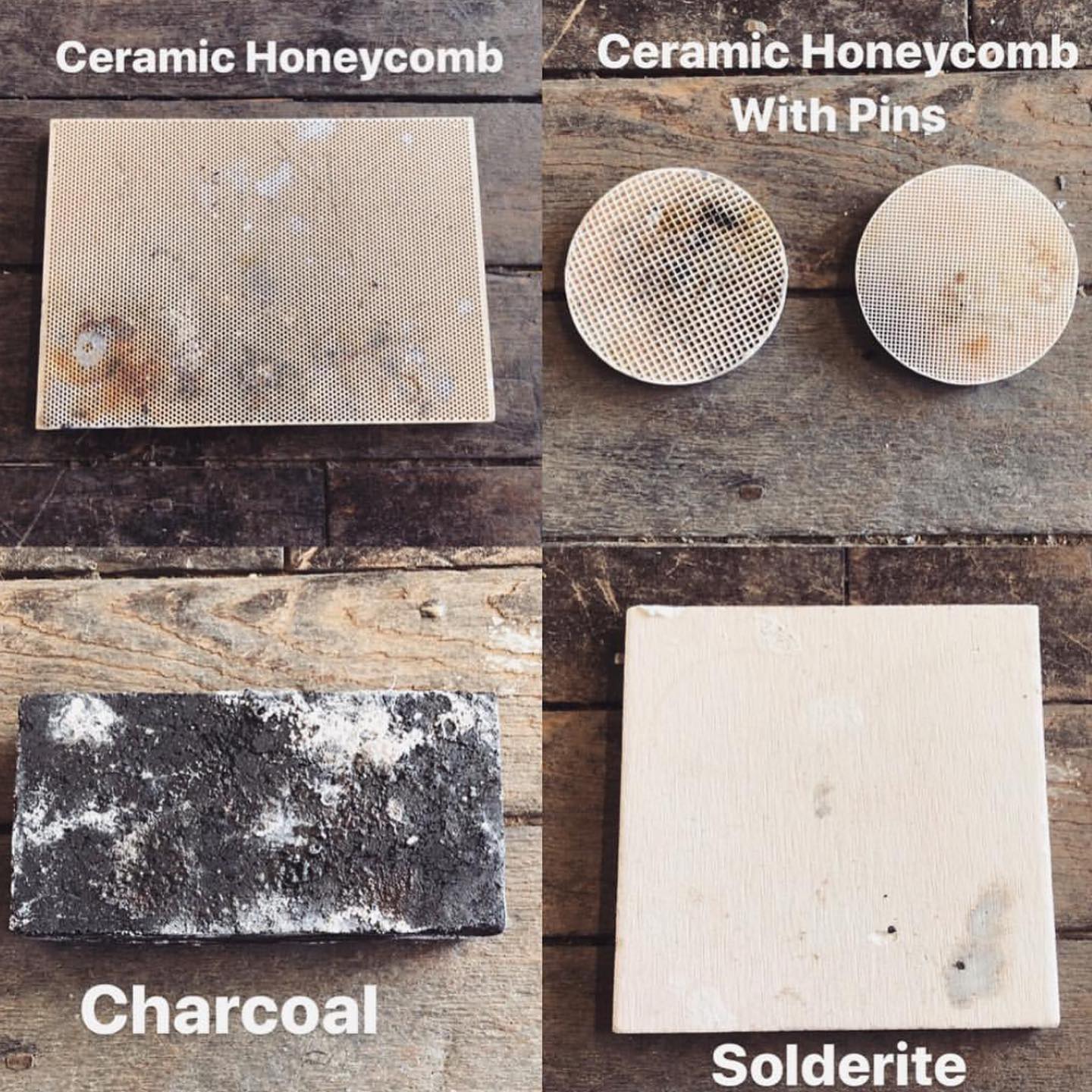

For this #tooltalktuesday I am bringing back a post from 2019 - SOLDERING SURFACES First we will discuss the honeycomb soldering board. They are lightweight and have tons of tiny holes, they don’t retain heat and cool quickly. They do reflect heat back onto whatever you are soldering which makes your flame more effective, this does mean you might have slightly more residue and oxidation. They are an ideal choice for soldering most projects except tiny things (which can fall through the holes) this constantly happens with my solder as well. They also make the small circular honeycombs with pins (those come in large and small and that refers to the hole size) and we’ve shown a bunch of tips with those, I love em! Charcoal is another option, they are also heat reflective. Charcoal is great for carving grooves to position small elements into, or sticking pins and binding wire into. For example, if you want to create a perfect ball, create a depression in the charcoal, fill it with scrap, and heat it until it balls. The downside of charcoal is that it can get crumbly and crack when heated. To make a charcoal block last longer, wrap the edges with binding wire before use. I tend to use hard charcoal as it’s more long lasting! Lastly I own a Solderite Board (calcium silicate) these boards are more dense so they don’t break or flake as easily. I find mine rapidly cools so it can be good for soldering smaller elements that I don’t want to melt. I don’t find myself using it for soldering larger things for that I prefer honeycomb or charcoal. You can also stick pins into solderite boards or even pieces of metal (like prongs) so great for positioning work. You can also draw a grid with a sharpie on your solderite to help with positioning.

Below all of this stuff I have a solid ceramic board, this protects my soldering table and I place my solder on it (hard on one side, medium on the other). What’s your favorite, what questions do you have? Let us know! #metalsmithsociety #solderingtools #solderingjewelry